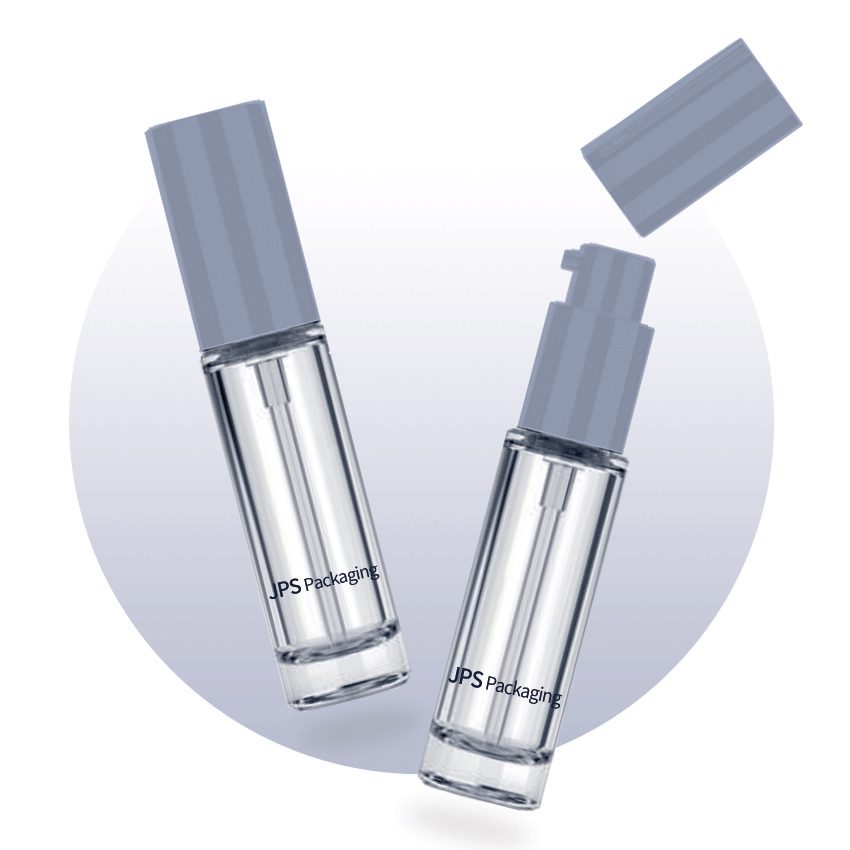

Glass Bottle Production for Skincare: A Comprehensive Guide to Crafting High-Quality Packaging

In the competitive skincare industry, packaging is more than just a container—it’s a reflection of brand values, product integrity, and consumer trust. Glass bottles stand out as the gold standard for skincare packaging, and their production process plays a pivotal role in ensuring they meet the unique needs of delicate formulations, eco-conscious brands, and discerning consumers. From raw material selection to quality control, every step of glass bottle production for skincare requires precision, expertise, and a focus on functionality. In this guide, we’ll take a deep dive into the world of skincare glass bottle production, covering key processes, critical considerations, and best practices to create packaging that protects your products, elevates your brand, and resonates with shoppers.

Why Skincare Demands Specialized Glass Bottle Production

Skincare products are often formulated with sensitive, active ingredients—such as retinol, vitamin C, hyaluronic acid, and essential oils—that require packaging to maintain their potency, freshness, and safety. Unlike generic glass bottles, those designed for skincare undergo specialized production to address these unique needs:

Chemical Inertness: Skincare glass bottles must be chemically stable to avoid reacting with active ingredients, which could compromise product efficacy or cause contamination. Production processes prioritize materials and treatments that ensure non-reactivity.

Barrier Protection: The production process must create glass bottles with superior barrier properties, shielding products from light, air, and moisture—all of which can degrade formulations over time.

Hygiene Standards: Skincare packaging comes into direct contact with skin, so production must adhere to strict hygiene protocols to prevent contamination during manufacturing.

Sustainability Alignment: With eco-friendly beauty on the rise, skincare glass bottle production increasingly focuses on recycled materials, energy-efficient processes, and recyclable end products.

Key Stages of Glass Bottle Production for Skincare

Crafting a high-quality glass bottle for skincare is a multi-step process that combines traditional techniques with modern innovation. Here’s a breakdown of the core stages:

Raw Material Selection: The Foundation of Quality

The production process begins with choosing the right raw materials, as they directly impact the bottle’s durability, safety, and performance:

Glass Composition: Most skincare glass bottles are made from soda-lime glass or borosilicate glass. Soda-lime glass is cost-effective, versatile, and ideal for standard skincare packaging (e.g., jars, dropper bottles). Borosilicate glass is more heat-resistant, durable, and chemically stable, making it perfect for premium products or formulations that require extra protection (e.g., serums with high concentrations of active ingredients).

Recycled Content: To meet sustainability goals, many manufacturers incorporate recycled glass (cullet) into the raw material mix. Recycled glass reduces energy consumption during production (by up to 30%) and minimizes waste. High-quality skincare glass bottles often use 30-100% recycled cullet, depending on brand requirements.

Color Additives: For UV-sensitive skincare products, colorants are added during raw material mixing to create amber, green, or frosted glass. Amber glass is the most popular for light-sensitive formulations, as it blocks up to 99% of harmful UV rays. These additives are carefully selected to ensure they don’t affect the glass’s inertness or the product’s integrity.

Melting and Forming: Shaping the Bottle

Once raw materials are mixed, the production moves to melting and forming—where the glass transforms from a powder mix to a usable bottle shape:

Melting: The raw material mix is fed into a furnace heated to 1,500–1,600°C (2,732–2,912°F). This intense heat melts the mixture into a molten glass that is homogeneous and free of bubbles (a critical detail, as bubbles can weaken the glass or create aesthetic flaws).

Forming Techniques: Two primary methods are used for skincare glass bottle production:

Blow and Blow Process: Ideal for small to medium-sized bottles (e.g., dropper bottles, 10–30ml vials). The process starts with a “gob” (a small, measured amount of molten glass) dropped into a mold. Compressed air blows the glass into a preliminary shape (parison), which is then transferred to a second mold to be blown into the final bottle shape. This method ensures consistent wall thickness and precise dimensions—essential for skincare bottles that need to fit closures (e.g., droppers, pumps) perfectly.

Press and Blow Process: Used for larger bottles, jars, or containers with wider mouths (e.g., cream jars, 50–100ml bottles). A plunger presses the molten glass into a parison mold, and compressed air then blows it into the final shape. This technique creates thicker, sturdier walls, making it ideal for heavier formulations like creams or masks.

Customization During Forming: Brands looking for unique packaging can incorporate customization at this stage. Embossed logos, unique contours, or textured surfaces are created by designing custom molds. Frosted finishes can also be applied during forming (via mold textures) or later in the process (via sandblasting).

Annealing: Strengthening the Glass

After forming, glass bottles are fragile and contain internal stresses from rapid cooling. Annealing is a critical step to strengthen the glass and prevent breakage:

The bottles are fed into an annealing lehr (a long, temperature-controlled oven) where they are heated to 500–600°C (932–1,112°F) and then slowly cooled over several hours. This gradual cooling relieves internal stresses, making the glass more durable, resistant to thermal shock, and less likely to crack during transportation or use.

For skincare bottles, annealing is especially important—they need to withstand daily handling (e.g., being dropped, exposed to temperature changes) and the weight of closures (e.g., pump dispensers).

Finishing: Enhancing Functionality and Aesthetics

Finishing touches transform raw glass bottles into polished, brand-ready packaging. This stage includes:

Trimming and Deburring: Excess glass (e.g., at the bottle neck or base) is trimmed away, and sharp edges are smoothed to ensure safety and compatibility with closures.

Surface Treatments:

Frosting: Achieved via sandblasting or chemical etching, frosted glass adds a luxurious, soft finish that hides fingerprints and elevates brand aesthetics. It’s popular for premium skincare lines.

Coatings: Some bottles receive a protective coating (e.g., silicone or acrylic) to enhance scratch resistance or improve grip. For clear glass bottles, anti-reflective coatings can make the product inside more visible.

Branding: Screen printing, hot stamping, or labeling is applied to add brand logos, product names, ingredient lists, or sustainability claims (e.g., “100% Recycled Glass”). These branding elements are carefully applied to ensure they adhere to the glass and resist wear during use.

Quality Control: Ensuring Compliance and Consistency

Skincare glass bottle production requires rigorous quality control (QC) to meet industry standards and brand expectations. QC checks are performed at every stage:

Raw Material QC: Testing the glass mix for purity, consistency, and recycled content.

In-Process QC: Inspecting bottles during forming and annealing for defects like bubbles, cracks, uneven wall thickness, or misshapen necks (which could affect closure fit).

Final QC: Checking finished bottles for:

Dimensional accuracy (e.g., height, diameter, neck size) to ensure compatibility with closures and dispensers.

Strength and durability (e.g., drop tests, pressure tests).

Hygiene (e.g., ensuring bottles are free of dust, debris, or contaminants).

Aesthetic consistency (e.g., uniform color, no scratches, crisp branding).

Compliance Checks: Ensuring bottles meet global safety standards (e.g., FDA regulations for cosmetic packaging, EU REACH standards) to confirm they are safe for contact with skincare products.

Critical Considerations for Skincare-Focused Glass Bottle Production

To ensure your glass bottles align with skincare product needs and brand goals, keep these factors in mind during production:

Compatibility with Formulations

Work closely with your glass manufacturer to select materials and production processes that won’t react with your skincare ingredients. For example:

Acidic formulations (e.g., exfoliating toners with AHAs) require glass that is highly resistant to corrosion—borosilicate glass is a better choice than soda-lime glass here.

Oil-based products (e.g., facial oils, serums) need bottles with tight-sealing necks to prevent leakage, so production should prioritize precise neck dimensions and smooth finishes.

UV Protection Integration

If your product contains light-sensitive ingredients, incorporate UV protection directly into the production process:

Use color additives (amber, green) during raw material mixing to create inherently UV-protective glass.

For clear glass bottles, consider adding a UV-protective coating during finishing or pairing the bottle with a UV-blocking outer box (though integrating protection into the glass itself is more effective).

Sustainability in Production

Consumers increasingly choose brands with eco-friendly practices, so optimize your glass bottle production for sustainability:

Source raw materials from suppliers that offer recycled cullet.

Use energy-efficient furnaces and annealing lehrs to reduce carbon emissions.

Design bottles for recyclability (e.g., avoid non-recyclable coatings or mixed materials) and clearly label them as “100% Recyclable.”

Offer refillable options by producing durable bottles that can be easily cleaned and refilled—this extends the bottle’s lifecycle and reduces waste.

Closure and Dispenser Compatibility

Skincare glass bottles are only as good as their closures—production must ensure the bottle’s neck and finish are compatible with your chosen dispensing system:

For dropper bottles: The neck size must fit the dropper’s rubber bulb and glass pipette snugly to prevent leakage and ensure precise dispensing.

For pump bottles: The neck thread must match the pump’s threading, and the bottle’s interior must be smooth to allow airless pumps to function effectively.

Collaborate with your manufacturer to test closure compatibility during sample production to avoid issues during full-scale manufacturing.

Scalability and Cost-Efficiency

If you’re launching a skincare line or expanding, ensure your glass bottle production process is scalable:

Choose a manufacturer with the capacity to handle small-batch runs (for testing) and large-scale production (for full launches).

Opt for standard mold sizes if cost is a concern—custom molds are more expensive upfront, but they can be cost-effective for high-volume production or premium brands.

Consider wholesale production to reduce per-unit costs, especially if you’re planning to scale quickly.

Choosing the Right Manufacturer for Skincare Glass Bottle Production

Partnering with an experienced manufacturer is key to achieving high-quality, consistent glass bottles. Look for these qualities:

Skincare Packaging Expertise: Choose a manufacturer that specializes in cosmetic or skincare glass packaging, as they understand the unique requirements (e.g., formulation compatibility, hygiene standards) better than general glass producers.

Customization Capabilities: If you need unique designs (e.g., custom shapes, embossing, frosted finishes), ensure the manufacturer offers in-house mold design and customization options.

Sustainability Commitments: Verify that the manufacturer uses recycled materials, energy-efficient processes, and offers recyclable end products. Ask for certifications (e.g., ISO 14001 for environmental management) to back up their sustainability claims.

Quality Control Protocols: Inquire about their QC processes to ensure they meet global safety standards and deliver consistent, defect-free bottles.

Sample Testing: A reputable manufacturer will provide samples for you to test with your formulations, closures, and branding before full-scale production.

Conclusion

Glass bottle production for skincare is a precise, multi-faceted process that requires careful attention to material selection, formulation compatibility, sustainability, and quality control. By understanding each stage of production and partnering with the right manufacturer, you can create glass packaging that not only protects your skincare products but also elevates your brand, resonates with eco-conscious consumers, and stands out in a crowded market. Whether you’re launching a luxury serum line or an eco-friendly cream collection, investing in high-quality glass bottle production is a decision that pays off in product integrity, customer trust, and long-term brand success.

Ready to bring your skincare glass bottle vision to life? Contact our team of experts to learn more about our customizable, sustainable production solutions tailored to the unique needs of skincare brands.

share

Searching for sustainable, cost-efficient packaging that fits your brand?

Contact us today!