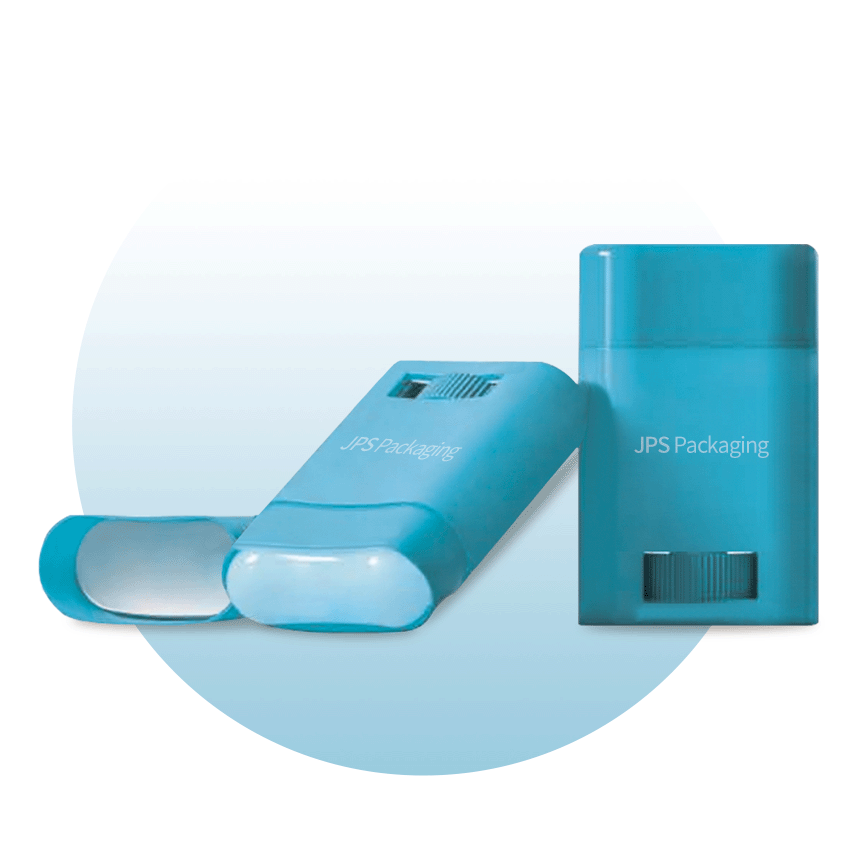

Beauty Stick Packaging Production: Steps, Materials & Quality Standards

The beauty stick market is blowing up—think lip balms, contour sticks, and solid serums—and packaging is make-or-break for grabbing shoppers’ attention. Beauty stick packaging production blends precision, material know-how, and eye-catching design to create solutions that protect your product, sell it on shelves. In this guide, we break down the ins and outs of getting it right, so brands can nail their packaging from concept to shelf.

The Basics of Beauty Stick Packaging Production

Beauty stick packaging production starts with one question: What does your product need to do? Unlike bulky makeup compacts, beauty sticks rely on sleek, functional designs—twist-up mechanisms, retractable tips, or sturdy casings—that hold up to on-the-go use. The process has to balance durability with curb appeal.

First, you’ll lock in key specs: product size, how it’s used (facial vs. body, daily vs. occasional), and who’s buying it. A luxury contour stick might call for premium materials and a chic finish, while a drugstore lip balm needs budget-friendly, lightweight packaging that still feels reliable. These choices steer every step of production, from picking materials to final assembly.

Material Picks: The Backbone of Great Packaging

Materials make or break beauty stick packaging production—they need to play nice with your product, fit your brand values, and resonate with eco-conscious shoppers. Here are the go-tos:

Plastics (PP & PE): Polypropylene and polyethylene are staples for a reason. They’re durable, flexible, and affordable, plus easy to mold into custom shapes. Most are recyclable in curbside programs , which checks the eco box for many shoppers.

Aluminum: Perfect for premium or sustainable brands, aluminum is lightweight, 100% recyclable, and keeps products safe from moisture and oxidation. It also has a sleek, modern vibe that screams “high-quality.”

Cardboard & Paperboard: Great for outer packaging, these materials are biodegradable, customizable, and level up the unboxing experience.

Sustainability isn’t just a trend anymore—it’s a must. More brands are choosing recycled materials, biodegradable plastics, or packaging that’s easy to recycle, thanks to growing demand consumers who care about the planet.

How Beauty Stick Packaging Gets Made

The manufacturing process depends on materials and design, but here’s the breakdown of key steps:

Injection Molding: For plastic parts (like twist-up mechanisms or casings), injection molding is the name of the game. Plastic resin gets melted down and shot into custom molds, so every piece is consistent in shape and size—no wonky casings here.

Cutting & Shaping: Aluminum or cardboard gets cut and shaped (think die-cutting or extrusion) to fit your design. Aluminum might also get anodized for extra durability or fun color options.

Assembly: Components (casings, twist mechanisms, caps) are put together by hand or machines—super important for twist-up sticks, where smooth functionality is everything. No one wants a stick that gets stuck mid-twist!

Finishing Touches: Printing (brand logos, product details), coatings (matte, glossy, or textured), and quality checks. These steps make your packaging stand out on drugstore shelves or luxury beauty counters.

Quality control is huge in beauty stick packaging production. Inspectors check for cracks, misalignments, or broken parts, test how well twist mechanisms work, and make sure everything follows industry rules. It’s all about making sure your packaging is reliable and looks great.

Quality Standards & FDA Compliance

Beauty stick packaging production has to follow strict rules to keep shoppers safe and meet U.S. regulations. Key standards include:

Safety First: Packaging can’t have toxic stuff (like BPA or phthalates) that leaches into the product. The FDA keeps a close eye on this, so brands have to make sure materials are non-toxic.

Functionality: Twist-up or retractable parts need to work smoothly every time. No jamming, no breaking—shoppers expect their beauty sticks to hold up to daily use.

Labeling Rules: Labels have to include ingredients, expiration dates, and recycling info, and follow FDA guidelines (and state-specific rules, too).

Most brands partner with FDA-compliant manufacturers to make sure their beauty stick packaging production checks all the boxes. Third-party testing can also prove that materials are safe and packaging works, which builds trust with shoppers.

Trends Shoppers Love

Beauty stick packaging production is always changing, and these trends are winning over shoppers:

Minimalism: Clean lines, neutral colors, and simple designs—shoppers love the sleek, luxury feel without the clutter.

Customization: Unique shapes, personalized printing, or limited-edition finishes help brands stand out. Shoppers love feeling like they’re getting something special.

Eco-Friendly Designs: Recyclable materials, refillable casings, or zero-waste packaging—this isn’t just a trend, it’s a dealbreaker for many eco-conscious buyers.

Multi-Use Packaging: Packaging that doubles as something else (like a reusable case or a travel-friendly container) adds value and reduces waste.

Staying on top of these trends helps your beauty stick packaging resonate with shoppers and stand out in a crowded market—whether you’re selling at Walmart, Sephora, or online.

Picking the Right Production Partner

Finding a reliable manufacturer is key to great beauty stick packaging production. Look for partners who:

Have experience making beauty stick packaging (not just general packaging—specialization matters).

Can handle custom designs and sustainable materials.

Follow FDA rules and have strict quality control processes.

Can work with small batches or large production runs (depending on your needs).

Working closely with your manufacturer ensures your vision comes to life, and your packaging is high-quality, functional, and perfect for shoppers.

Wrapping Up

Beauty stick packaging production is all about balancing function, style, and compliance. From picking the right materials to nailing the manufacturing process, every step affects how your product performs on shelves and with customers. By focusing on quality, sustainability, and what shoppers actually want, brands can create packaging that protects their product, builds brand loyalty, and drives sales. Whether you’re launching a new beauty stick or updating your packaging, getting the production right is the first step to success.

share

Searching for sustainable, cost-efficient packaging that fits your brand?

Contact us today!