Torque Guide for aluminum bottle for skincare and beauty stick packaging: Achieve Perfect Seals Every Time

Torque is the rotational force applied during cap application or removal from a container. When applying a closure to a containerlike aluminum bottle for skincare or beauty stick packaging, it is important to utilize the correct amount of torque to ensure a proper seal. Ideally, torque should be evenly distributed throughout the closure, whether you’re capping a sleek aluminum bottle for skincare or a compact beauty stick packaging unit.

What Is Torque and Why Does It Matter?

Torque directly impacts the functionality and safety of cosmetic packaging. For aluminum bottle for skincare—used for serums, lotions, or toners—proper torque prevents leaks and preserves product freshness. For beauty stick packaging—popular for concealers, highlighters, or lip balms—correct torque ensures the stick mechanism operates smoothly without jamming or breaking. Both aluminum bottle for skincare and beauty stick packaging rely on balanced torque to meet consumer expectations and industry standards.

What Are the Key Torque Types?

APPLICATION TORQUE: The rotational force with which a closure is applied to a bottle finish during capping. It affects seal integrity and tightness between bottle and closure—critical for aluminum bottle for skincare that holds liquid formulas prone to leakage. For beauty stick packaging, application torque ensures the cap locks firmly to prevent the stick from retracting unexpectedly.Properly established application torque will provide sealing integrity under expected conditions or temperatures, humidity and shock.

REMOVAL TORQUE: The rotational force with which a threaded closure is removed or unscrewed from a bottle finish. It defines the amount of rotational force necessary to loosen, open, or remove the closure. A properly designed package—whether aluminum bottle for skincare or beauty stick packaging—should have a removal torque range appropriate for its intended use and the consideration of any requirements for child resistant or tamper evident closure needs. A pack with a tamper evident closure will have two separate removal torques. The first is the torque to make the closure start to move, the second torque is the opening force required to break the tamper evidence system on that pack (Generally the second force will be dependent on the type of tamper band being used). This is especially vital for aluminum bottle for skincare with potent ingredients and beauty stick packaging targeted at family-friendly markets.

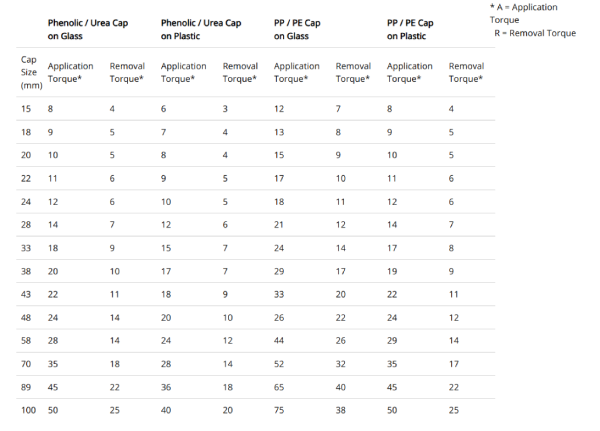

STRIPPING TORQUE: The application torque which is sufficient to cause the closure and/or bottle finish to distort and override the matching closure/bottle threads, resulting in loose caps, no seal, or package component deformation. For aluminum bottle for skincare, over-torquing can dent the bottle neck or strip threads, ruining the container. For beauty stick packaging, excessive torque can crack the plastic housing or break the stick mechanism. The following torque values are listed for use as guidelines only, and are to be used for closure application by hand under controlled conditions. Special conditions may require torque values other than those listed. The actual figure you set will be dependent on many other variables, including the material of aluminum bottle for skincare or beauty stick packaging, liner type, filling temperature, capping head and if the pack is passing through an induction tunnel.

How Are Torque Values Measured?

TORQUE VALUES: Torque is defined in inch-pounds or Newton meters and is measured by various types of torque meters. Specific methods for performing torque tests are defined in Technical Bulletin PBI No. 7. The optimum relationship between applied and removal torques and good sealing characteristics under various physical and environmental conditions must be established for each individual package, whether it’s a lightweight aluminum bottle for skincare or a durable beauty stick packaging. Application torque requirements also vary according to the closure size being used for both aluminum bottle for skincare and beauty stick packaging.

Note: Immediate removal torque values are approximately 40 80% of application torque values. Production capping equipment should be adjusted to produce similar immediate removal torque values. It is important you test packs 30 days after application as this will be more indicative of the of the removal force the consumer will experience opening your finished pack.

Debunking a Common Myth About Torque

Myth:The tighter you apply a closure the less likely the chance the product in the container is going to leak.Fact:Applying too much pressure to a closure can actually increase the chances of product leakage.

Over-torquing may cause some points on the cap to have more pressure then others, which could result in an improper seal. If the cap is applied with too little torque, the container may leak or the closure could come off too easily.The chart below illustrates the recommended torque to apply or remove closures of a specific size and material. The figures are based on the minimal amount of torque needed to apply or remove a closure. As a general rule, the amount of torque is about half of the diameter of the cap. Torque is expressed in inches per pound.

As always, since packaging variables come into play, be sure to test your specific application to ensure optimal results and safety. The most accurate way to measure torque is with a torque tester.

share

Searching for sustainable, cost-efficient packaging that fits your brand?

Contact us today!